HDPE Root Barrier

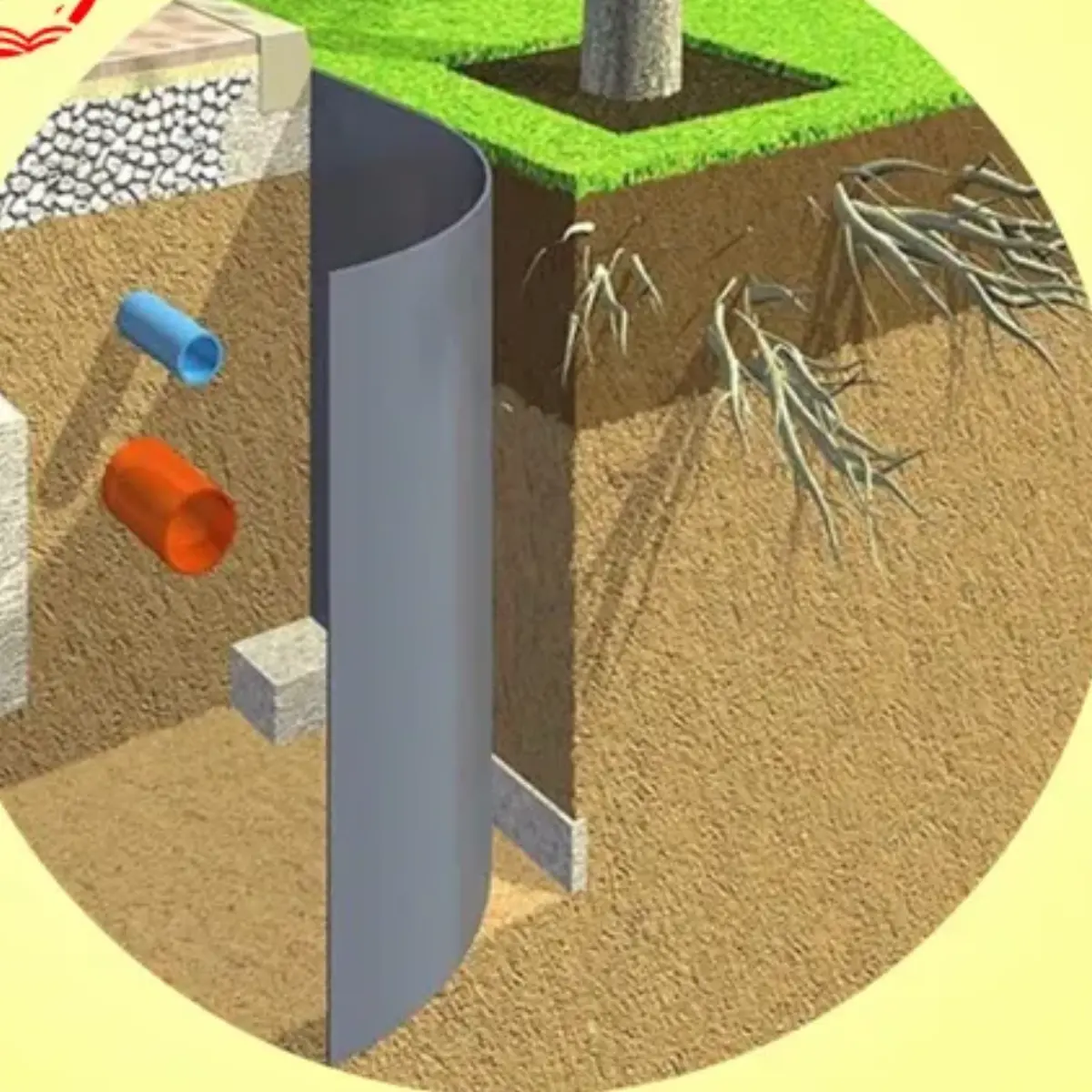

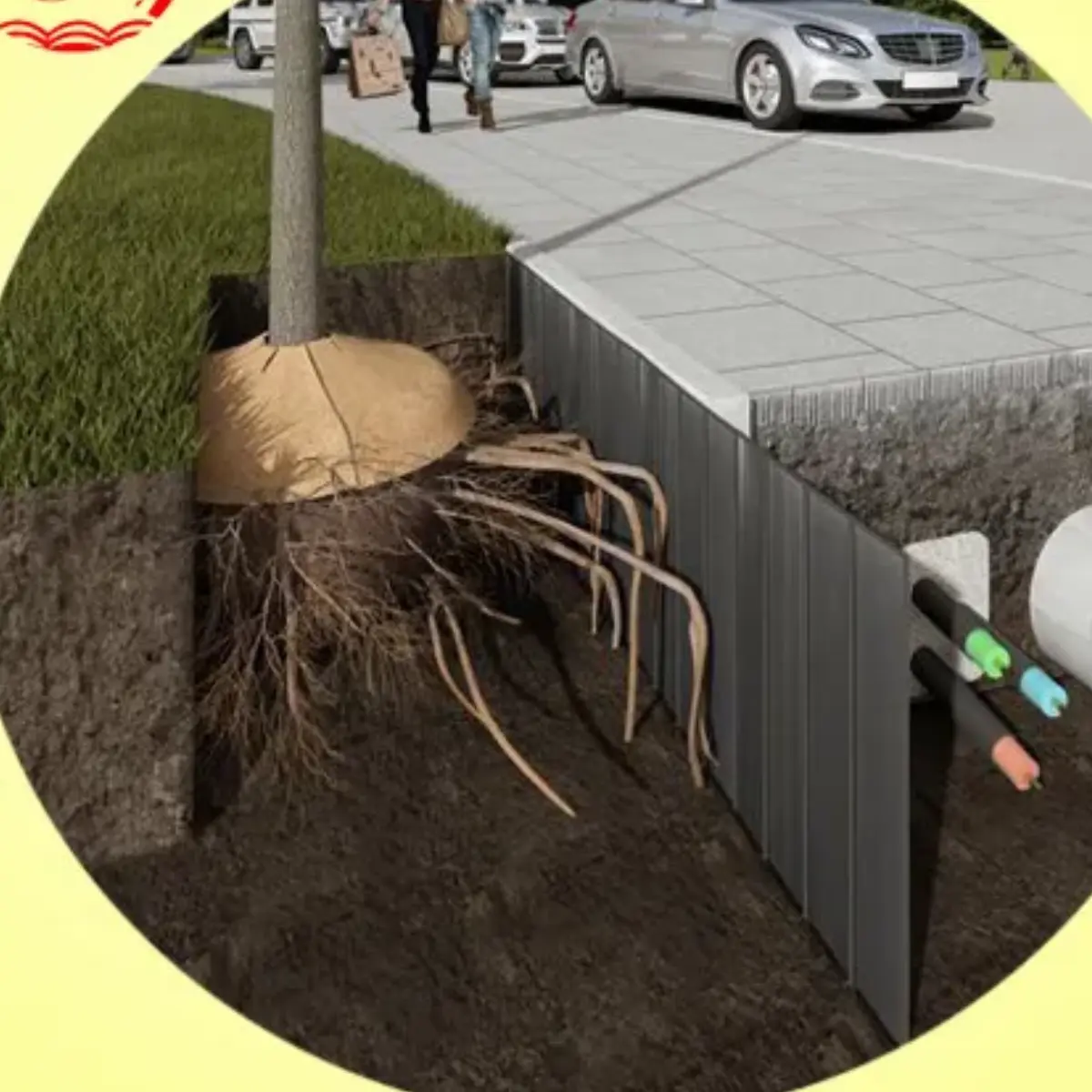

HDPE Root Barrier : While walking on a paved road or driving on the highway then you must have noticed that there is a kind of plastic barrier which is called an HDPE Root Barrier. This product is made from High-Density Polyethylene or HDPE sheets and HDPE Plastic Sheets . This Root Barrier is very suited to protect the Cables, Sewage Pipes and ducts against mechanical pressures such as Excavators. This product is specifically designed to restrict Invasive and unwanted root growth.

The HDPE Root Barrier is considered very ideal for landscaping needs, Foundations of Buildings and also for paved areas. This barrier also acts as a barrier for the preservation against the tree roots and moisture seepage to prevent kerb, driveway and house foundation damage. This Root barrier is a waterproof adaptable covering that is made from high-density polyethene plastic sheets and is stabilized to comply with D1505 and ASTM D5199.

Features:

- Ease of Use: HDPE Root Protection covers are designed for user-friendly application. Their straightforward installation process ensures that anyone can utilize them effectively.

- Cost-Effectiveness: One of the standout qualities of HDPE Root Barriers is their cost-effectiveness. Their competitive pricing makes them a budget-friendly option for root management, minimizing financial strain during installation.

- Recyclable Material: These barriers are made from recyclable HDPE material. This means that they can be easily recycled, including both the outer cover and inner core, reducing environmental impact.

- Chemical Inertness: HDPE Root Barriers possess the valuable trait of being chemically inert. This ensures that they remain stable in various soil conditions, even in the presence of different chemicals.

- Adjustability: These barriers are designed with flexibility in mind. Their adaptability allows for easy adjustments according to specific conditions and available space, ensuring efficient root containment.

- Durability and Flexibility: HDPE Root Barriers are engineered to be tough yet highly flexible. They can be welded or taped together, allowing for seamless customization to fit any area.

Advantages:

- Structural Shield: These Root Barriers act as protective shields for structures against the intrusion of tree roots. This protective measure is vital for maintaining the integrity of foundations and other structures.

- Root Guidance: HDPE Root Barriers guide tree roots to grow deeper into the soil, discouraging the development of larger, potentially damaging roots. This guidance prevents the growth of invasive roots that can harm structures.

- Moisture Regulation: The barriers effectively trap and divert harmful roots, preventing them from extracting moisture from buildings and structures. This moisture regulation ensures that structures remain unaffected by root-induced moisture loss.

These HDPE Root barriers are very useful for numerous reasons. Some of the applications where this is used are mentioned below.

- Pathways: They are ideal for protecting pathways from root encroachment, ensuring safe and undisturbed passage.

- Landscaping: These barriers are valuable for maintaining the aesthetics and functionality of landscaped areas, preventing root-related damage.

- Individual Trees: For safeguarding individual trees and managing their root growth near structures.

- Structure Footings: Protecting the foundations of structures from potential root damage.

- Concrete Paths and Pipes: Preventing root intrusion into concrete paths and pipes, which can lead to costly repairs.

- Roadway Construction: Applicable in both new and existing roadway construction to safeguard against root interference.

HDPE Root Barriers meet stringent specifications:

- Recyclable: Manufactured from 100% HDPE sheets, the barriers contribute to sustainable practices through recyclability.

- UV-Proof: Their UV resistance ensures that the barriers maintain their integrity even in prolonged sun exposure.

- Recycled Material: Some variants are made with recycled materials, promoting eco-friendly manufacturing.

- Chemical Resistance: These barriers exhibit high resistance to bacteria and most chemicals, enhancing their longevity.

- Durability: Thick, robust construction renders the barriers impenetrable to aggressive roots and mechanical pressures, ensuring their long-lasting performance.

Related products

Hdpe T Rib Liner Sheets

- Flexible Liner Sheet: HDPE T Rib Liner Sheets exhibit a flexible nature, allowing them to conform to different shapes and surfaces. This flexibility ensures a snug fit even in challenging applications.

- Good Tear Strength: These liner sheets possess impressive tear strength, making them highly durable and resistant to damage, ensuring long-lasting performance.

- Locking Extensions: These sheets come with locking extensions, enhancing their ability to securely attach and interlock, providing a seamless protective layer.

- Permanent Grip: The "T" structure of the liner sheets ensures a firm and permanent grip, which is crucial for maintaining stability and preventing slipping or shifting.

- Acid and Solvent Resistance: HDPE T Rib Liner Sheets demonstrate excellent resistance to acids, solvents, and corrosive chemicals. This resistance ensures they remain unaffected even when exposed to aggressive substances.

- Gas and Alkali Resistance: These liner sheets are capable of withstanding gases like hydrogen sulphide and alkalis, contributing to their overall longevity and reliability.

- Easy Repairs: If the liner sheets sustain damage, they can be easily repaired without the need for extensive replacement, minimizing downtime and maintenance costs.

- Frictional Resistance: The excellent frictional resistance of these sheets prevents slippage and enhances stability, especially in applications where movement is a concern.

- Good Welding Potential: HDPE T Rib Liner Sheets offer good welding potentiality, allowing for efficient and effective jointing, further reinforcing their structural integrity.

- Strong Jointing: The liner sheets provide a solid jointing strength, creating a cohesive protective layer that can withstand various stresses and pressures.

- Sulphuric Acid Resistance: These sheets are resistant to sulphuric acid, a highly corrosive substance, making them suitable for environments where such chemicals are present.

- High Abrasion Resistance: HDPE T Rib Liner Sheets exhibit high resistance to abrasion, reducing wear and tear over time and maintaining their integrity.

- Corrosion Protection: These liner sheets offer exceptional protection against corrosion, safeguarding underlying structures and equipment from deterioration.

- Reduced Water Consumption: By preventing leaks and damage, these liner sheets contribute to lower water consumption and efficient resource management.

- Chemical Protection: HDPE T Rib Liner Sheets shield pipelines from aggressive chemicals, ensuring the integrity and safety of the transported substances.

- Improved Sewerage Flow: Compared to concrete, these liner sheets enhance the flow of sewerage, minimizing blockages and improving system efficiency.

- Moisture and Humidity Resistance: Even when exposed to humidity and water, these liner sheets remain unaffected, maintaining their performance and structural integrity.

- Bacteria and Fungus Resistance: The liner sheets are resistant to sanitary bacteria and fungus, making them suitable for environments where cleanliness is essential.

- Flexibility and Smoothness: T-rib liners are both flexible and smooth, enabling them to adapt to various surfaces while ensuring optimal flow characteristics.

- Low Maintenance Cost: In comparison to concrete, these liner sheets have lower maintenance requirements, reducing ongoing maintenance expenses.

- Extended Lifespan: HDPE T Rib Liner Sheets have a longer lifespan than concrete, providing prolonged service and reliability.

Reviews

There are no reviews yet.