Geocell

LS Trading, a renowned HDPE Geocell manufacturer, exports premium-quality, durable geocells for optimal soil stabilization and landfill site. We export our products worldwide including the USA, United Kingdom, United Arab Emirates, Australia, and Gulf Countries. Call us or enquire about Geocell Price Now.

LS Trading is the best Geocell Manufacturer worldwide. We always produce the best quality products by keeping the Customer’s needs in mind. You can always trust our products as we have a team of industry experts who always strive hard to provide an excellent product.

With every passing day, the world is upgrading itself. As technology is constantly developing, there’s no way out except to adopt it in every utilization. In the modern era, construction has taken a prominent part which can’t be progressed without implementing the right technological solution. Here comes the significance of employing a geocell solution! This one of robust technology is primarily used for earth stabilization.

Alternatively known as Cellular Confinement Solutions, the revolutionary honeycomb matrices are vastly applied in many infrastructure projects. Besides soil reinforcement, this modern technology is reliable for enhancing the drainage system. Since 1970, it has been applied to military roads in hilly regions for the utmost stabilization of the earth. You often see this high-duty solution in constructing railways and highways in various corners of the world. To protect steep slopes, there’s no better alternative to Geocell solutions. If you deeply research modern engineering methods, it will be clear that this hi-tech solution is the best means for earth protection.

Geocells are used for ground improvement while constructing temporary and permanent roads. The porous and granular surfaces made by Geocells increase the load-bearing magnitude of roads and minimize construction costs.

To protect unpaved roadways on soft soil, Geocells are the ultimate solution that provides rigidity and resistance to deformation. They also make hindrance against shrinking in clay, alleviate lateral dispersion, and strengthen the sub-grade soft soils. In preserved terrain, parking surfaces are covered with vegetation to impact the environment positively.

Maintaining roads with Geocell reinforcement systems keeps them in proper condition. Roads are more likely to experience frequent issues due to weakening characteristics of subsoil, which result in dents, rutting, washing out, and damage to unpaved surfaces. Besides roadways, local forestry, Parish surfaces, fire escape routes, and other places can be improved by employing Geocells.

Geocells are often filled with soil, sand, or gravel to create a strong foundation for roads, parking lots, and other paved surfaces. They can also be filled with lighter materials, such as wood chips or straw, for landscaping projects. Geocells are versatile and can be adapted to a variety of needs.

Features:

- Used as load transferring platform

- Effective in soil stabilizing

- Lightweight yet very strong

- Made of virgin HDPE Material

- High strength

- Installation very easy

- Versatile solutions for roads and highways

- Proven 3d Geocells for soil stability challenges

- Transforms Infill unlike any other Geosynthetics

- Makes soil strong – Confines and stabilizes soils

- The engineered solution to meet any design challenge

Advantages:

- Lowers the cost

- Effortless deployment

- Lifelong performance

- Flexible and permeable

- This is very cost-effective for building unpaved roadways

- Solving many engineering, infrastructure, and construction challenges

- Improve shear strength of granular soil

- Prevent erosion problems

- Solved unacceptable road problems

- Geocell used for Slope Protection

- Landscape Decks

- Load support

- Basement retaining walls, gravity walls

- Erosion control

- Ground stabilization

- Channel protection

- Earth reinforcement

- Shorelines

- Pond Filtration Systems

- Parking Areas and Walkways

- Bridge Abutments

- Roadways Embankments

- Steep Slopes

- Vegetated slopes

- Stormwater channels

- Ditch Protection

- Slope liner protection

- Sports fields

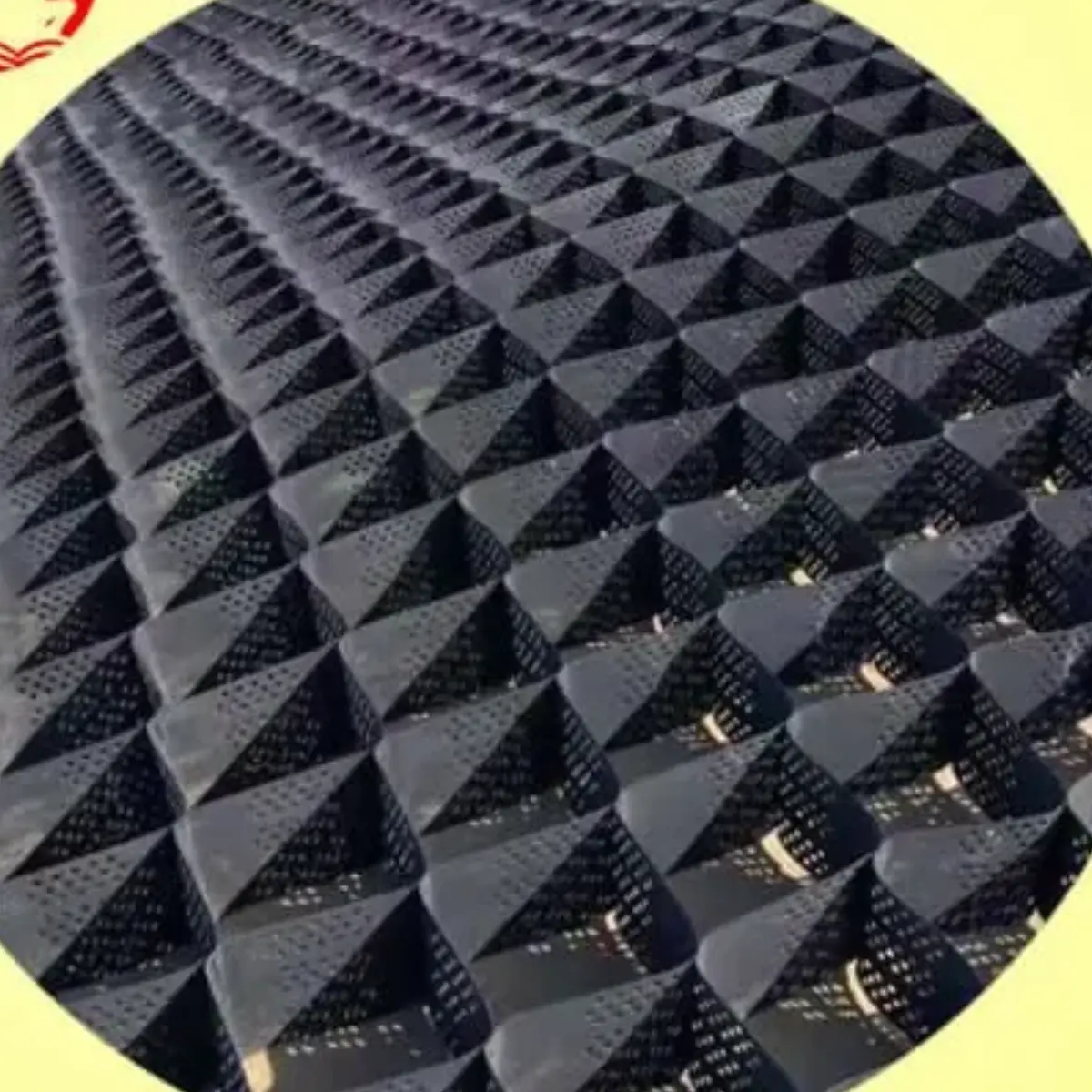

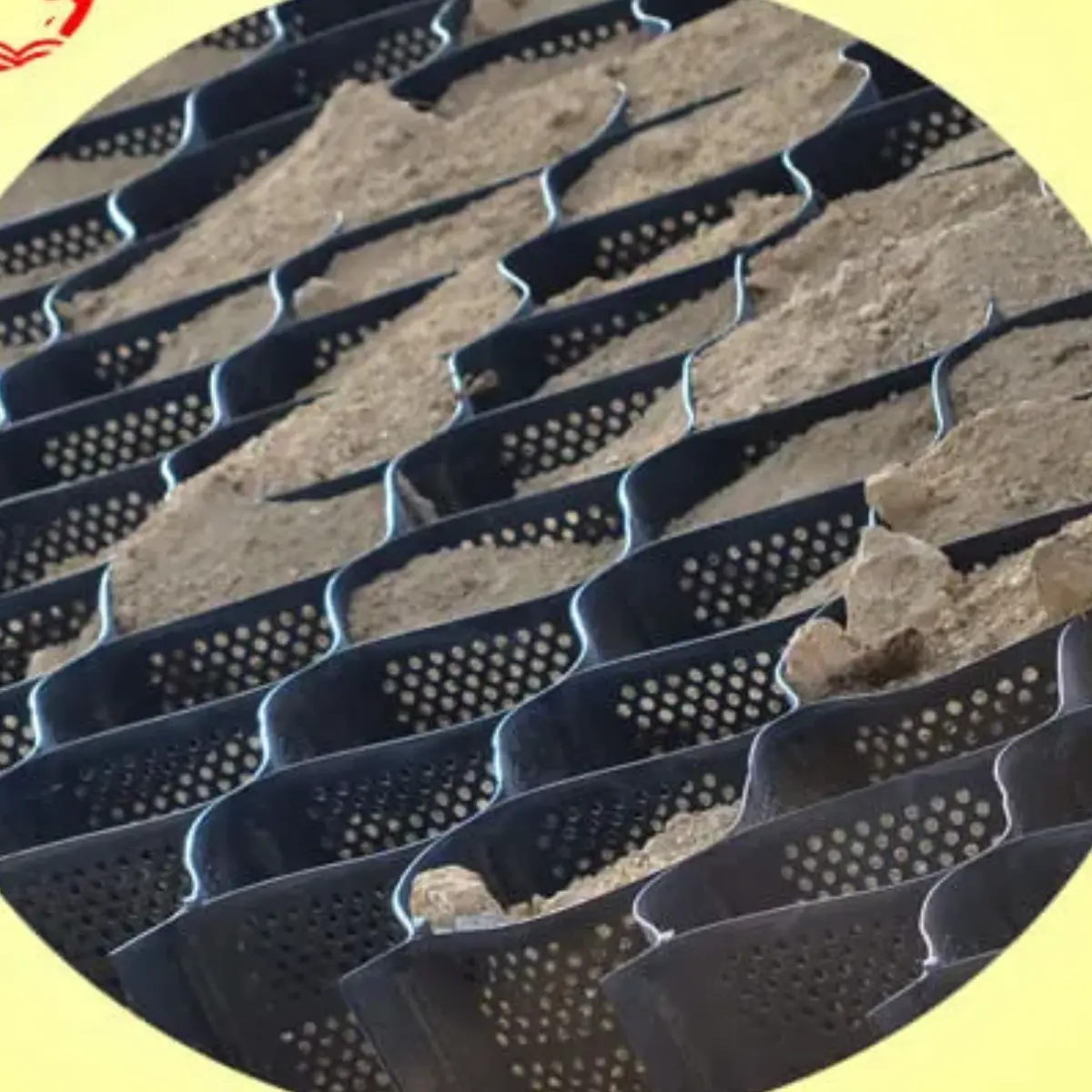

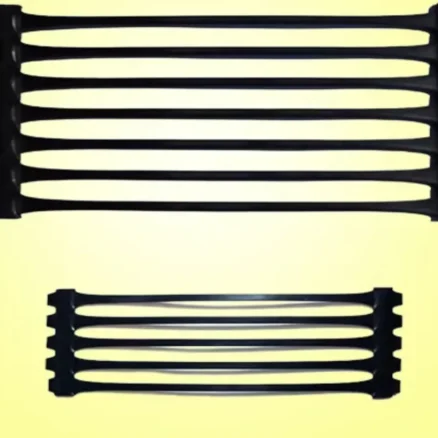

A geocell is a three-dimensional honeycomb-like structure made of polymeric material used in civil engineering. It is usually made from high-density polyethylene (HDPE) or polypropylene (PP) and is used to reinforce soil in various applications, such as road construction, landfill engineering, and soil stabilization.

Geocells are manufactured in a variety of sizes and shapes. The most common geocells are rectangular or square in shape, although triangular and hexagonal geocells are also available. The size of the geocell depends on the application. For example, geocells used in road construction are typically larger than those used in soil stabilization.

The honeycomb-like structure of the geocell provides a high-strength, low-weight reinforcement system. The cells are interconnected, creating a three-dimensional network that distributes loads evenly. This network of cells also allows for quick and easy installation.

Following are the standard specification. Customization can be done as per the customer’s requirement.

- Product Type – smooth and not perforated, smooth and perforated, textured and not perforated, and textured and perforated.

- Height(mm) - 50≤H≤250

- Welding Distance(mm) - 330≤A≤1000

- Thickness(mm) - 1.0~1.4, 1.5~1.7 or as required

- Tensile Strength of Welding Points(N/cm) - ≥100

- Tensile Strength of Connection of Cells(N/cm) - ≥120

- Tensile Strength at Yield of Each Sheet(MPa) - ≥20

Our company has a team of experts who can provide you with various sizes, shapes, styles, and colors of PP Multifilament Yarn to meet your unique specifications.

Related products

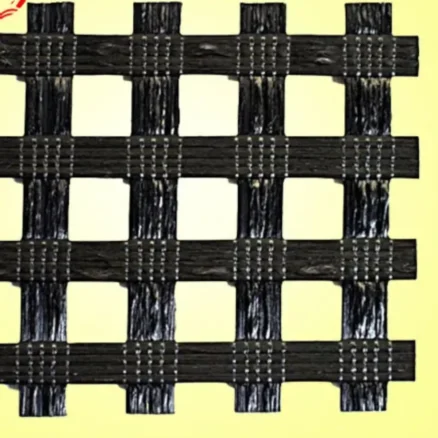

Biaxial Geogrid Manufacturer and Supplier

- Porches

- Driveways

- Barricade

- Railroads

- Airport Runways

- Car Parks

- Construction Haulage Roads

- High intersection quality and firmness

- High elasticity at low extension

- Low inclination to crawl

- Simple to introduce, protection from establishment harm

- High synthetic and natural opposition

- Streamlined framework structure and proficient rib profile for expelled Geogrids

- Magnificent draw-out and interface grinding conduct

- Unrivaled association limit with secluded squares

- Protection from ecological pressure breaking

- Effortlessly associated together on location

- Advance soil adjustment

- Give a higher burden-bearing limit

- Adaptable in nature and are notable for their flexibility

- Have high toughness, which diminishes support cost

- They are profoundly impervious to natural impacts

- Anything but difficult to introduce which brings about quicker development

- The simplicity of Construction: PP Biaxial Geogrid can be introduced in any climate conditions, making it all the more requesting

- Land Optimization: This strategy for Geogrid establishment in soils makes an inadmissible zone reasonable for setting it up to meet wanted properties for development. Geogrid, in this way, helps inappropriate land usage

- It is a decent solution for holding soil from disintegration

- No trouble in material accessibility

- Known for their excellent flexibility

- Possess high toughness, diminishing upkeep cost. It is profoundly safe against natural impacts.

- Materials are tried dependent on standard codes and guidelines

Geo Bags – Geotextile bags

It is also known as:-

- Geo Bag

- Geotextile Bag

- Non-Woven/Woven Geo Bag

- Geotextile Sand Container

- Sand Bags

- These bags are considered flexible and cost-effective solutions for the construction off-shore protection structures.

- These bags come with excellent durability and robust strength.

- The market is filled with various sizes and strengths of geo bags best suited for specific applications.

- Compared to the traditional marine protection stuff, geo bags are a highly accessible and feasible option.

- There's a high demand for geotextile bags across the different infrastructure projects for their reduced carbon footprint and minimal environmental effect.

- With the proper usage of geo bags, soli susceptible to erosion get transformed into defiant erosion sites.

- These bags are so versatile that they can be used for diversifying situations.

- In comparison to the expensive method of erosion prevention, the Geo sandbag is the most economical alternative.

- The design used in manufacturing geo bags guarantees longevity.

- The geo bags are environment-friendly, and it doesn't negatively impact the environment and abruptly reduce the harmful carbon footprint and disturbance in the site.

- Installing these geotechnical bags is so convenient that it reduces time and cost.

- The advanced mechanical and filtration ensures enhanced usage and maximum efficiency.

- The efficient usage of geotextile bags enhances the speed of construction sites, thus achieving the desired results.

- Ideal solution for coastal, off-shore, and waterfront structures that requires specific protection

Geotextile – Geotextile fabric – Geotextile Sheet – Geotextiles

- Resistance to UV exposure

- High tensile strength

- Soil separation and drainage

- High durability

- Good physical and hydraulic properties

- Low elongation

- Resistant to rot and degradation

- Resistant to biological organisms

- Uses heavy multifilament

- Excellent support to large rock overlays

- Good support under the roadways

- Strengthens soil

- Controls erosion of any area

- Decreases structural failure

- Reduces maintenance costs

- Easy installation

- Versatile and practical in usage

- Improves performance

- Cost-effective and economical

- Made with strong fibers

- Tightly Woven

Geomembrane Sheet

- Texture and Finish Options: The HDPE geomembrane liner is available in both textured and smooth finishes, providing adaptability to different usage scenarios.

- Temperature Conductivity: Remarkably conductive in high-temperature variations, making it suitable for applications requiring thermal stability.

- Chemical Resistance: Possesses excellent resistance to a wide range of chemicals, enhancing its usability in challenging industrial and environmental settings.

- UV Protection: Offers a reliable ultraviolet protection shield, making it suitable for outdoor applications where exposure to sunlight is prevalent.

- Weather Durability: The geomembrane sheet exhibits exceptional age resistance against the intense stresses of weather, maintaining its integrity over time.

- Welding and Molding: Designed for easy welding and molding, allowing for convenient installation and customization according to project requirements.

- UV Stabilization: Manufactured using UV stabilizers, which enhance its weather resistance capacity and overall longevity.

- Puncture and Water Resistance: Demonstrates high puncture resistance, making it adept at withstanding mechanical stress, and exhibits outstanding water resistance.

- Tensile Strength: Boasts high tensile strength, contributing to its robustness and ability to withstand various mechanical forces.

- Longevity: Designed for long-term use, the geomembrane liner offers extended service life standards, minimizing the need for frequent replacements.

- Roll Format: Supplied in wide rolls for efficient handling and application, available with single or double-sided textured surfaces.

- Easy Installation: The geomembrane's user-friendly design allows for straightforward installation processes.

- Versatile Applications: It finds applications in diverse fields, ranging from waste management and water containment to waterproofing structures.

- Environmental Protection: Utilized in waste and water management, it contributes to environmental conservation by preventing leaks and contaminations.

- Thermal Aging Resistance: Its resistance to thermal aging ensures reliability and effectiveness over the long term.

- Non-Toxic: Made from non-toxic materials, the geomembrane poses no harm to the environment or human health.

- Chemical Resilience: Exhibits resilience against numerous chemical agents, expanding its applicability in various industrial settings.

- Cost-Effective: The geomembrane offers an economical and cost-effective solution for lining requirements, reducing overall project expenses.

- Mechanical Strength: Its impact and tear resistance, along with excellent flexibility, contribute to its robustness and adaptability.

- Reliable Soldering: The geomembrane's superior soldering ability ensures secure joints and a dependable containment system.

- Efficient Transport: Designed for easy transport due to its roll format, facilitating convenient logistics and handling.

- Minimal Risk: The geomembrane's construction eliminates the risk associated with micro-probes, ensuring enhanced safety during application.

Geonets – Geonet in Road Construction

- Chemical Resistance and Aging Resistance

- Erosion Resistance

- Excellent Flexibility and Durability

- Tensile Strength

- It can be made with all polymeric materials

- It provides shear strength

- Harder than geotextiles and have large voids within the material

- Prevents the surface of the land from the erosion

- Protecting dam and rock surface from chemical erosion and sea water corrode

- Strengthen fill materials in geotechnical applications

- Used as liquid or gas collectors

- Used widely in drainage applications

- Improve the quality of the road

- Road segment restoration

- Stop cracking during road extension

- Cost reduction of road repair

- Increase the lifespan of the road

- UV stabilized

Uniaxial Geogrid

- They provide a stable foundation for plant growth and prevent erosion by water and wind

- They resist compaction and improve aeration and drainage

- They reduce the amount of water required to retain moisture in the soil

- They improve the physical and chemical condition of the soil by holding more air, water, and nutrients.

- Good Creep Resistance

- Quick Installation

- High Tensile Strength

Polyester Geogrid

Polyester Geogrid has many advantages over traditional materials, including:

- It is resistant to moisture and fungus

- It is lightweight and easy to transport

- It can be easily dyed or printed to match your needs.

- It is fire-proof, making it an excellent choice for outdoor use.

Reviews

There are no reviews yet.