Material For Infrastructure Works

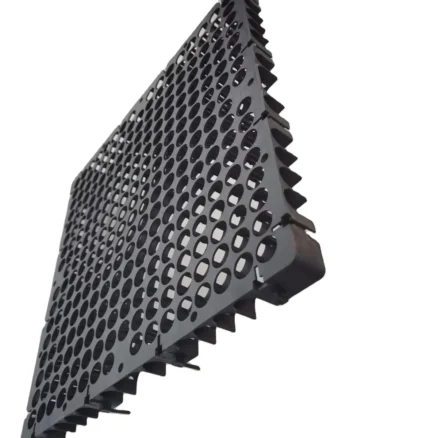

Ground Covers

We are leading manufacturers at LS Trading, present with our quality products. It exports premium quality, highly durable Ground Covers manufactured by us using the best grade of thermoplastic material, i.e., Polypropylene. Ground cover is the best solution to lure moisture into the soil. It also helps restrict weed growth by allowing the water to pass through.

Ground cover is a type of plant that grows low to the ground and helps to hold soil in place, reduce weeds, and create a colourful landscape. They are low–maintenance and well–suited to many types of terrain. There are several types of ground cover plants, including perennials, evergreens, and annuals.

Ground covers are specially designed to allow water to penetrate into the soil, ensuring that the crops get proper sunlight and at the same time restricting insects and protecting them without damaging wildlife. The said Ground Cover is manufactured by weaving the Polypropylene tapes together. They possess great strength and are highly durable. We offer HDPE ground cover mats that last for long life in direct heat and sunlight.

HDPE Ground cover mats manufacturer plants have shallow root systems, which helps them to spread quickly and fill in areas quickly. Ground cover can be used to cover large areas such as slopes, hills, and banks, as well as small areas such as rock gardens and pathways.

Ground Cover usually has marker lines every 12" for proper plant alignment. It helps retain the soil's moisture and maintains the soil temperature. These covers are flexible in application and used in landscape situations for insect protection, weed control, temperature control, frost prevention, etc. Ground covers are the best choice for horticultural applications and aesthetic appearances. They are available in different weights, colors, widths, and lengths. These covers resist tearing, puncturing, and weed penetration, saving time and money! Ground covers can be used in varied applications depending on your choices.

These woven black polypropylene HDPE Ground Cover Mats supplier are stabilized using an ultraviolet stabilizer which acts as the perfect weed barrier for planting areas while still allowing moisture to pass through your vegetables and plants. UV stability and UV retention are obtained with the help of circular loom fabric. Our Ground Cover Fabric is the best solution for your landscaping ventures.

Features:

- Very effective in blocking weeds and soil erosion

- Due to its water-absorbent quality, it allows the soil to breathe.

- Prevents soil/land washout due to rainfall

- Used for 100% chemical-free weed control

- Having high tensile strength

- Highly durable

- Tough and tear-resistant

- Highly resistant to UV & chemicals and mildew

- Provides cost-effective covering

- Long-lasting and optimum quality

- Lightweight

- Easy to maintain and clean

- Our manufactured woven Ground Covers are sturdy and durable, having a life expectancy of 5+ years.

- Our ground covers are available in square marking lines, and stripes, which can be customized per the customer’s requirement.

- Our manufactured fabric is treated with UV stabilizers that provide a longer life to the end product.

- Our Ground Covers have specific green lines over the fabric, making overlapping easier.

- 100% chemical-free weed control

- Prevents/blocks weed growth

- Time saver in maintaining flower beds

- It has many Beautifies the landscape as the plants can be planted in straight parallel lines for neat and clean landscaping in nurseries and farms.

- Our Ground Covers are UV stabilized and can be used multiple times.

- Having good resistance to mildew, bacteria, and other ground/soil insects

- Possess long-term durability

- It prevents soil and land erosion to an extent.

- Good in regulating temperature in all weather conditions

- Stabilizes land and soil to an extent

- It can be reused over many seasons.

Silt Fence

LS Trading is an Erosion control silt fence manufacturer in India. The company offer silt fences to help prevent soil erosion and water pollution. Our silt fence is made with high-quality polyethylene fabric and galvanized steel wires. The silt fence is easy to install, durable and can be customized to fit any size and shape of your site.

Our silt fences are used in construction sites, residential areas, and other areas that require soil erosion and water pollution control. Singhal Industries Private Limited also offer installation services along with the silt fences. We ensure that our silt fences are properly installed to ensure maximum efficiency.

The purpose of an Silt Fence is to hold the dirt on upset/disturbed lands, for example, a building/construction site, until the task is finished. Keeping the soil on-site, rather than letting it be washed off into natural water bodies (e.g., streams, rivers, ponds, lakes, estuaries), prevents the degradation of aquatic habitats and siltation of harbor channels. Not letting soil wash off onto roads and readily transporting it into storm drains prevents hazardous driving conditions and storm drains from getting clogged with sediment. It also controls silt which gets run-off from job sites, while allowing water to pass through the fabric while collecting leftover sediment.

The Environmental Protection Agency (EPA) has recognized the Silt fence installation as a storm-water best management practice (BMP). Silt Fence is profoundly practical as though you analyze the expense of introducing Silt Fence at watershed building destinations to the expenses related to losing amphibian species, digging route channels, and clearing dregs out of city storm sewers, which is excessively less. The cost of installing Silt fences on watershed construction sites is also too low compared to the cost of losing aquatic species, dredging navigation channels, and cleaning sediment out of municipal storm sewers. 50 tons of sediment can be held by installing a single 100 feet Silt fence.

Erosion control silt fences are a type of sediment control device used to help filter and trap sediment-laden water runoff before it enters natural water sources. The silt fence is typically made of a fabric material installed in a trench that runs across the area where erosion occurs.

The fabric material is then filled with earth or rocks to help act as an additional filter that traps sediment before entering the water source. These silt fences can be installed in areas such as construction sites, along highways, or in agricultural areas where erosion is a potential issue.

Features:

- Makes a physical boundary around the site

- UV stable dark fence texture

- Logo printing accessible

- Keep mud off roads and neighboring property

- Straightforward plan and straightforward establishment

- Ensure streams

- Holds silt on the place of work

- Channels overflow before leaving the site

- Assists with forestalling disintegration

- Accessible with or without stakes

- Preassembled fence with presents joined on texture

- Marker line on texture shows anchor profundity

- Forestall exorbitant place of work materials from depleting off

- Keep streets and streams liberated from contamination

- Light to medium quality woven textures

- Steel backing is likewise accessible for improved execution

- Endorsed for DOT use in numerous states

- Shield residue from leaving building locales

Weed Mat

We are a Weed Mat manufacturer and supplier made in India with high-quality materials such as woven polyethylene or polypropylene. It is used to suppress weed growth, prevent grass from growing, protect plant roots from sunlight, and provide necessary drainage to the soil below. The fabric in the weed mat allows adequate passage of water into the soil below. It helps in retaining and nourishing the moisture in the soil. It is lightweight and easy to install.

Weed mat, also known as landscape fabric, weed barrier, or weed control fabric, is a synthetic fabric that prevents weeds from growing in garden beds and landscaping areas. It is usually made of polypropylene or polyester and comes in various thicknesses and widths. Weed mat has many advantages over traditional weed control methods, such as tilling and mulching, as it is more effective and eliminates the need for herbicides. It is also more durable and can last up to 10 years.

It keeps the fertilizer goods and water from evaporating. It can effectively prevent the ground from producing weeds and keep the floor neat and clean. It is widely used in agriculture farms and home gardens. It helps to prevent the grass from growing unnecessarily and also protects from UV rays. We offer weed control mat in different weights, colours, widths, and lengths as per customer requirements and specifications.

Using chemicals to kill the weed can be an easier and more effective way, but it is not a healthy option. Garden weed barrier fabric is much in demand due to its non-toxic feature and it helps to grow the plant healthily. It prevents the growth of weeds and control soil moisture as well. It also protects plants during various weather conditions, helps in road surface protection, seedbed protection and it reduces herbicide usage. To grow plants or flower beds, they need a sufficient amount of water and nutrition. Due to unwanted weed, the growth of the plants or flower bed is affected badly, also destroying their existence. Hence garden weed mats play a vital role in stopping weeds from growing. And it is one of the best eco-friendly ways to protect the plants and flower beds from unwanted weeds. Hence before buying weed mats, you may measure the area properly, so that you can get the exact and perfect size for your application.

Our professionals are highly experienced and our quality testing team always ensures that weed control mat manufacturers to keeping in mind strict measures of quality control by following international standards. We maintain the highest quality of the Garden weed mat and provide the best service to our customers.

Features:

- Strong, durable and long lasting

- Prevents weeds growth in agriculture farms, nurseries, greenhouses, etc.

- UV resistance

- Boosts plant growth

- Water saving and reduces the use of herbicide

- Durable

- Air and water can pass easily

- Resistance against fungus and tears

- Prevents weed growth

- Strong tensile resistance

- Long term durability

- Prevents erosion

- Regulates temperature

- Soil stabilization

- Prevent grass growing in agricultural farm

- A cheap and appropriate way to prevent weed growth

- Environment friendly

- Non-toxic method to stop the growth of weed compared to chemical weed killer

Roofing Underlayment

We, LS Trading, are one of the leading and well-known manufacturers of Roof Underlayment produced with advanced technology. Roofing is an essential part of any property, and selecting the proper roof underlayment is crucial for any structure. The roof underlayment is designed in such a way for more strengthen the life and performance of any roof.

The primary role of roofing underlayment is to act as a barrier material providing resistance against water, wind, or any other severe weather conditions and providing extra protection to your roof. It is generally installed on the roof deck.

There are different types of Synthetic Roofing Underlayment like 1) Asphalt-saturated felt, 2) Synthetic underlayment, and 3) Rubberized asphalt underlayment. The first two are water resistant, and the third one is waterproof underlayment.

- Asphalt-saturated felt is described as felt paper and is made from organic; hence it is called an organic underlayment. It is generally applied throughout the roof deck and is recommended considering local weather conditions. It is used in residential and steep slope applications as it is water resistant and not waterproof.

- Rubberized Asphalt is a bit costly compared to the other two underlayments, as it has a good amount of asphalt and rubber polymers to build it waterproof and is more suitable in regions where it is severe winter. Such underlayment is used at Eaves, Valleys, and surfaces with low slope roofs.

- Finally, the most demandable roofing underlayment is roofing underlayment suppliers, also called non-bitumen synthetic underlayment. Synthetic roofing underlayment gives the roof an additional surface of safety that is not possible solely with shingles. It is lightweight and thin compared to asphalt felts. Moreover, the installation process is also very easy. It is a tough, durable, and high strength, designed in such a way that it prevents skidding and improves walkability during installation due to its unique textured fabric. It is resistant to moisture, UV damage, tears, leaks, and fungal growth and is wrinkle-free even when exposed to the elements. It is available in longer and wider rolls; hence it gets fewer trips up the ladder due to fewer rolls.

Our professional and highly experienced quality testing team always ensures that the Roofing Underlayment Exporters, keeping in mind strict measures of quality standards. To maintain the highest quality of the Roof Underlayment and provide the best service to our customers.

Features:- Stop water infiltration

- Extended UV Exposure

- Capture less heat

- Good resistance to water and vapor

- Tear and puncture resistance

- Slip resistance walking surface

- ISO authorized

- Tough and Durable Material

- Extreme weather protection

- Prevent from skidding during installation

- High temperature tolerance

- Water and fire resistant

- Wrinkle-free when exposed to the elements

- Simple and Quick Installation

- It won’t absorb water

- Increase job site productivity due to lighter rolls

- Does not require extra equipment

- Better leak protection

- More flexible in the cold

- Clean and easier to handle

- Enhance walkability and the life of roof due to unique textured fabric

- More coverage per roll

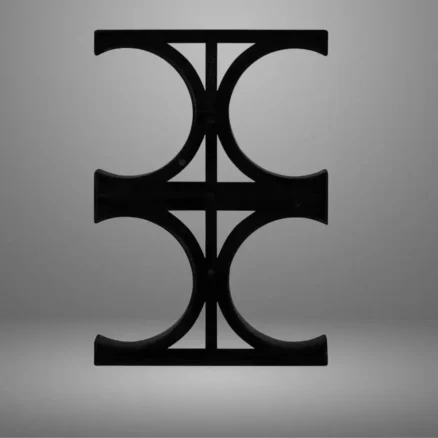

Drainage Cell

LS trading, a well-known manufacturers company in the world which provides the best Drainage cells. People call it by different names like drainage board, drainage mats, dimpled membrane, PP drainage mats, drainage plate, drainage cell mat, flo cell, etc. Drainage cell made with high high-strength interlocking panel system with 100% recycled polypropylene or virgin polypropylene.

It is very lightweight but can still hold up to 90 tonnes load. Due to lightweight & easy installation steps, heavy machines & technically skilled labour are not required. It is a three-dimensional geo-composite designed to provide the solution for sub-surface drainage systems, which helps in creating successful rooftop garden & planter boxes without any problem of cracking or leakage & it also works as an alternative for heavy aggregate drainage treatment. Excess water can be easily discharged out due to its uniform structure & void space, which helps to promote plant growth & helps to sustain a steady temperature on the wall surface. This drainage cell systems also controls water logging and decreases water pollutants.

Covering the drainage cell with non-woven fabrics helps water permeability and is used as a soak away system for rainwater from terraces, retaining walls, roof gardens, sports fields, basements etc. This drainage cell manufacturer board is also used to reduce hydrostatic pressure in-ground, reduce heat & cold, filtrate rainwater, and remove excess water.

Our professional, highly experienced quality testing team always ensures that drainage cell exporter, keeping in mind strict quality control measures by following international standards to maintain the highest quality and provide the best service to our customers.

Features:

- Highly durable

- Quick & easy to install

- Weather & chemical resistance

- Lightweight & easy to use

- Reliable performance

- Thermal regulation

- Water storage

- Resistance to puncture of plant roots

- Excellent drainage capacity

- Easily transportation

- Heat Insulation

- Water drainage

- High Compressive strength

- Waterproof polypropylene material

- Ventilation

- Cost effective

- Eco Friendly

- Helps water flow freely

- High flow rate

- Rapid & efficient drainage

- Versatile design can be fix horizontally or vertically

- Relieves hydrostatic pressure in the ground

- Strong structural design

- Long life expectancy

- Biologic resistant

- High Infiltration

- Preventing waterlogged ground

Rockshield Mesh

LS Trading is a well-known brand for manufacturing Rockshield Mesh. Rock shield is also called Rockshield Pipe Protection Net, pipeline net, pipeline protection mesh, rock shield mesh, and Rockshield Construction Net. The main role of Rockshield is to protect pipeline coating from rock backfills. It is manufactured from HDPE material and is available in 3-dimensional bi-planar high-strength extruded plastic mesh, mainly to protect the corrosion coating on pipelines laid in rocky terrain and rock backfills. It is applied in the shape of a diamond lattice structure.

This Rockshield mesh roll (a heavy-duty mesh) provides steady thickness all-round the width of each roll & protects pipeline coating from rock backfills. Its flexible mechanical protection padding acts as rock guard padding throughout the pipes during and after backfill operations. After installation, it protects the pipe by preventing damage by geologic movement. A Rockshield mesh price is necessary when pipelines are constructed near rocky shore as it protects the pipelines & it is flexible even at sub-zero temperatures.

It is used by many industries like Gas & oil pipeline, chemical industries, water industries, etc., as it is lightweight, flexible & easy to install, Impact & corrosion resistant, and cost-effective.

Our professional-quality team ensures that Rockshield Mesh manufacturers with strict quality control measures by following international standards to maintain the highest quality of the product & service to our customers.

Features:

- Apertures allow water flow

- Wear Resistance

- Corrosion Resistance

- Impact Resistance

- Tear Strength

- Elongation

- Tensile Strength

- Chemically inert

- Restrict geologic movements from damaging pipeline

- Minimizes impact and penetration damage

- Absorbs impact of uneven rock backfill

- Flexible event at sub-zero temperature

- Protects pipe coating from rock backfill

- Reduces abrasion of coating from pipe movement underground

- Protects pipeline during excavations

- Not influence by utmost temperature or wet weather

- Cushions against concrete weights

- Cuts with a utility knife

- Ample weight, thickness and strength protects pipeline

- No mechanical damage during backfilling operations

- Resistance to destructive forces

- Cost-effective alternative to sand collar

- Lightweight, flexible and easy to handle

- Minimizes pipeline coating damage which can cause corrosion

- Easy to install

- Provides pipeline & coating protection at affordable rate

- Maintains effectiveness of cathodic protection

- It will not Rot

- Protects pipe during loading, unloading & transportation

PP Woven Fabric

We, LS Trading, are one of the leading and well-known manufacturers, suppliers, and exporters of flawless Polypropylene Woven Fabric. We manufacture PP Woven Fabric like circular, flat, wide, etc., which is coated/uncoated with the latest technology on our finest circular looms and tape line machines. The company provides PP Woven fabrics that are very strong and durable. As it is of woven characteristics, it is very flexible, lightweight, and therefore used in various industries.

We manufacture laminated as well as non-laminated PP Woven fabric roll. Our PP woven fabric manufacturers are available in roll forms, making loading easier and smooth for any machines such as cutting, stitching, etc. Our PP woven fabrics are known in the market for their quality, durability, strong wear resistance, tear-proof nature, eco-friendly and cost-effective. They are much in demand in India as well as the International market.

LS Trading manufactures high-quality PP Woven Fabric, which is used for making many end products. The PP woven products include PP small bags, boxes, perforated bags, courier bags, FIBC Bags, cement bags, sugar bags, woven bags, ground covers, woven laminated bags, woven laminated gusseted bags, etc. PP woven fabrics are also used in many industrial sectors such as fertilizers, cement, chemicals, textiles, machinery and wheat, flour, fish, meal, and rice industries. Also, it is used to cover aircraft, trucks, railway wagons, open spaces, boats, industrial machines, and agriculture products at farms.

Features:

- High Tensile Strength and Durability: PP woven fabric boasts exceptional tensile strength, making it remarkably durable. This inherent strength ensures that the fabric can withstand considerable stress and pressure without tearing or breaking, enhancing its longevity.

- Heat Resistance: PP woven fabric exhibits a notable resistance to heat, which makes it suitable for applications where exposure to high temperatures is a concern. This characteristic helps maintain the fabric's structural integrity even under challenging conditions.

- Low Elongation: The fabric's low elongation property signifies that it retains its shape and dimensions even when subjected to stretching forces. This feature is essential for maintaining the integrity of the items or materials it encases.

- Improved Stiffness and Rigidity: PP woven fabric offers improved stiffness and rigidity, imparting stability to the items it envelops. This characteristic is especially advantageous for packaging and protecting items that require shape preservation.

- Gravure Printing in Multiple Colors: With the capability to be gravure printed in up to six colors, PP woven fabric allows for vibrant and intricate designs. This quality enhances its aesthetic appeal and branding potential.

- UV Stabilization: The fabric is UV stabilized, which means it can withstand prolonged exposure to sunlight without deteriorating or losing its structural integrity. This makes it suitable for outdoor applications.

- Strong Wear Resistance: PP woven fabric exhibits strong wear resistance, ensuring that it can withstand abrasion and friction without succumbing to damage. This makes it an ideal choice for rugged applications.

- Moisture and Tear-Proof Nature: The fabric's moisture-resistant and tear-proof properties make it reliable for safeguarding items from moisture damage and physical harm, ensuring their protection during transportation and storage.

- Coated and Uncoated Options: PP woven fabric is available in both coated and uncoated variations, providing versatility to cater to specific requirements. Coating options can offer additional attributes such as water resistance or enhanced strength.

- Economical and Eco-Friendly: PP woven fabric is cost-effective to produce and purchase, making it an economical choice for various applications. Furthermore, its recyclable nature aligns with eco-friendly initiatives.

- Long Lasting: The fabric's durability and resistance to wear and tear contribute to its extended lifespan, ensuring that items packaged within it remain protected for extended periods.

- Flexible and Lightweight: Despite its robustness, PP woven fabric retains flexibility and lightweight properties. This combination of features simplifies handling, transportation, and wrapping tasks.

- Recyclable: PP woven fabric is recyclable, promoting sustainability and minimizing environmental impact by reducing waste generation.

- Easy to Carry: The fabric's lightweight nature, along with its flexible characteristics, makes it easy to carry, whether during packaging, transportation, or other applications.

- Versatile Applications: PP woven fabric is utilized for various purposes, including covering items, packaging goods, and wrapping materials, showcasing its adaptability.

Plastic Tree Guard

LS Trading is a recognized and dependable plastics organization engaged in manufacturing, importing, and supplying various types of plastic netting and plastic films such as Extruded Plastic Nets, shade nets, tree guards, tree protectors, tree guard nets, polyethylene non-woven fabrics, reinforcement mesh, Plastic Tree Guard and packaging nets. Our products are in high demand among our customers due to their high quality, durability, and environmental friendliness.

We have become our client’s first choice for procuring our product line based on their requirements. LS Trading can manufacture our products following industry and client specifications with a solid infrastructure provide the best quality controllers which ensure the manufacturing and packaging unit.

Tree protection net is typically made of single-faced plastic, which protects the base of the trunk and keeps it dark, cool, and ideal for growth. Plastic sleeve tree guards are extremely simple because they are lightweight and highly customizable to any tree size. The obvious reason for using plastic tree protectors is to keep other wildlife out, such as rodents and rabbits. They also provide support during harsh weather conditions when young trees have weaker trunk strength; however, there are other important reasons to use plastic sleeve tree guards. The use of Tree protection net helps protect young or newly planted trees from winter sun damage caused by warm winter days followed by cold nights. Summer heat causes tree bark to expand, but freezing temperatures cause splitting. Regardless of the season, this splitting in the tree's bark can result in the burning or scalding of the newly exposed bark.

When properly installed, tree guards are most effective. When used with jute matting, they provide:

- UV protection.

- Protection from animals and bugs.

- Protection from wind damage.

- Protection from trampling/physical damage.

- Weed control.

- Made from recycled plastic

- Creates an ideal microclimate for young plant growth

- UV stabilized

- Scientifically proven to produce the best plant growth results

- Economical and cost-effective for large plantings

- Protects against spray drift and small animals

- Reusable for multiple planting seasons

- Common Sources of Tree Trunk Injury

- Rabbits and mice (like mice)

- Sun in the winter (sunscald, trunk splitting, etc.)

Spout Pouch

| Products Details | Classification |

|---|---|

| Bag Style | Stand Up, Flat Bottom, Side Gusset, Shaped Bag |

| Base Material | PET ( Polyester), LDPE, Aluminium |

| Pouch Size | Customized sizes available |

| Pouch Pattern | Plain & Printed |

| Color | Transparent, Single & Multi-Color |

| Thickness | 51 microns onwards |

| Sealing & Handle | Spout Top |

Plastic Carry Bags

LS Trading is a leading manufacturer and exporter of plastic carry bags, including retail carry bags, shopping plastic bags, and customized carry bags. We have a wide range of clients from over 80 countries worldwide, including India, the USA, the UK, Canada, Australia, and UAE.

We offer a wide range of plastic carry bag options to meet the diverse needs of our customers. Our product line includes:

-

- Plastic grocery bags: These bags are perfect for packaging and transporting groceries. They are made of clear plastic but partially translucent, and come in various sizes to accommodate objects of varying weights.

-

- Plastic shopping bags: These bags are a popular choice for retail stores and supermarkets. They are convenient for customers to carry their purchases and are often given out for free at the point of sale.

-

- Customized plastic carry bags: We offer custom printing options for our bags, allowing businesses to promote their company name and logo. These bags are perfect for marketing and advertising your business.

-

- Polyethylene Medium Density (MDPE): While not as transparent as Low-density Polyethylene (LDPE), medium-density polyethylene is less transparent than High-Density Polyethylene (HDPE). These bags typically have a higher strength than Plastic carry bag manufacturers but less flexibility. This kind of polyethylene is used on a significantly lesser level than HDPE and is often used for product packaging and disposal bags.

-

- Polyethylene Low Density (LDPE): Another popular polyolefin is low-density polyethylene (LDPE). These materials are either white or transparent when used to make bags. LDPE is frequently selected for consumer packaging when strength is not required, including bags for bread, paper, frozen meals, fresh fruit, clean clothing, etc. The material is transparent and shiny, and the bags used to make it are incredibly stretchable, flexible, and transparent. Additionally, they offer high moisture and wear resistance but only modest gas barrier qualities.

-

- Low-Density Polyethylene Linear (LLDPE): LLDPE or linear low-density polyethylene are similar in their properties and applications. LLDPE is preferred for various applications due to a few differences, though. In contrast to LDPE, which is often chosen for its greater clarity, ease of manufacturing, and better gloss, LLDPE is often chosen for its stronger compressive and impact strength and superior heat seal ability. Grocery, frozen food, waste, daily newspaper, and essential food bags are essential uses.

- Excellent Tensile strength

- Low water absorption

- Low-temperature resistance

- Good chemical stability and heat resistance

- Resistance to most alcohol, acid, and alkali

- Plastic bags are lightweight and thin.

- Flexible and versatile carrier bags

- Plastic Bag Packaging is Strong and Durable

- Plastic bags are a Budget-Friendly Alternative.

HDPE Duct Spacer

LS Trading manufacturer & exporter of HDPE Duct Spacer. It is a device used to maintain a fixed separation between multiple parallel conduits or ducts that are laid underground or on overhead structures. It is typically made of High-Density Polyethylene (HDPE) material which is known for its high strength, durability, and resistance to corrosion.

HDPE Duct Spacer is designed to support and protect the conduits from damage caused by external forces such as soil movement, seismic activity, and traffic loads. It also prevents friction between the conduits and reduces the risk of damage caused by the rubbing of the pipes.

The HDPE Duct Spacer is available in different shapes, sizes, and configurations to suit various conduit arrangements. Some designs allow for easy installation and removal of the Duct spacer price, while others provide a more permanent solution.

Overall, the HDPE Duct Spacer supplier is an essential component of any modern conduit installation, as it ensures that the conduits are correctly positioned, secured, and protected from damage, thus enhancing the overall longevity and reliability of the conduit system.

Features:

- Material: HDPE Duct Spacer is made from high-density polyethylene (HDPE), which is known for its excellent strength, durability, and resistance to environmental factors like UV rays, chemicals, and moisture.

- Design: The spacer is designed to maintain a constant separation between multiple conduits or ducts, which reduces the risk of damage from external factors like soil movement, seismic activity, and traffic loads. It also prevents friction between the conduits, reducing the risk of damage caused by rubbing.

- Easy Installation: The spacer is designed for easy installation, with most models featuring snap-on or clip-on designs that allow them to be easily installed and removed without the need for specialized tools.

- Longevity: Duct Bank Spacer has a long service life and requires minimal maintenance, making it a cost-effective solution for conduit installations.

- Durability: It is made from a high-density polyethylene material, which is known for its strength and durability. This material is resistant to impact, abrasion, and weathering, making it ideal for use in harsh environments.

- Corrosion Resistance: HDPE Duct Spacer is highly resistant to corrosion, which makes it an ideal material for use in underground and overhead installations.

- Easy Installation: It is designed for easy installation, with most models featuring snap-on or clip-on designs that allow them to be easily installed and removed without the need for specialized tools.

- Versatility: HDPE Duct Spacer is available in a variety of shapes, sizes, and configurations to suit different conduit arrangements. Some designs allow for easy adjustment of spacing between the conduits, while others provide a more permanent solution.

- Cost-effective: It is a cost-effective solution for maintaining separation between multiple conduits and ducts, protecting them from damage, and ensuring the longevity and reliability of conduit systems.

- Environmentally friendly: HDPE Duct Spacer is an environmentally friendly material, as it is made from a non-toxic and recyclable material.

HDPE Duct Coupler

LS Trading manufacturer, exporter & supplier of HDPE Duct Coupler. A PE duct coupler, also known as a polyethylene duct coupler, is a type of fitting that is used to connect two pieces of polyethylene ductwork. Polyethylene ductwork is a popular choice for underground ducting and piping applications due to its flexibility, durability, and resistance to corrosion.

PE duct couplers are typically made from high-density polyethylene (HDPE) material, which is known for its high strength and resistance to abrasion, chemicals, and weathering. They are available in a range of sizes, ranging from small diameters of 20mm up to large diameters of 630mm or more.

HDPE duct coupler are designed to connect two pieces of polyethylene ductwork together in a secure and leak-free manner. They have a simple design consisting of two cylindrical pieces, one of which has a slightly larger diameter than the other. The larger piece is inserted over the end of one piece of ductwork, while the smaller piece is inserted over the end of the other piece of ductwork. The two pieces are then pushed together and secured in place with a locking mechanism, typically a clamp or a compression fitting.

Using a PE (polyethylene) duct coupler supplier is a relatively simple process that can be done with a few basic tools. Here are the steps to follow:

- First, ensure that the ends of the ducting or pipe that you want to connect with the coupler are clean and free of debris or rough edges.

- Slide the PE duct coupler over one end of the ducting or pipe until it reaches the center of the coupler. Make sure that the coupler is aligned properly with the end of the ducting or pipe.

- Repeat step 2 with the other end of the ducting or pipe, sliding it into the other side of the duct coupler price until it reaches the center.

- Use a wrench or pliers to tighten the coupler's grip on both ends of the ducting or pipe. This will ensure a tight and secure connection.

- If necessary, use a sealant or adhesive to create an airtight or watertight seal between the ducting or pipe and the coupler.

- Finally, test the connection to ensure that it is secure and leak-free.

- High Strength: HDPE duct couplers are made from high-density polyethylene, which is a strong and durable material. This means that they are able to withstand heavy loads and pressures, making them ideal for use in underground applications.

- Chemical Resistance: HDPE is highly resistant to a wide range of chemicals, including acids, alkalis, and solvents. This makes it ideal for use in industries where exposure to harsh chemicals is common.

- UV Resistance: HDPE duct couplers are also highly resistant to UV radiation, which can cause other materials to degrade and break down over time. This makes HDPE an ideal choice for outdoor applications where exposure to sunlight is a concern.

- Corrosion Resistance: Unlike metal couplers, HDPE duct couplers are highly resistant to corrosion. This makes them ideal for use in underground applications where moisture and soil can cause metal components to rust and deteriorate over time.

- Flexibility: HDPE is a flexible material, which means that it can bend and flex without breaking. This makes HDPE duct couplers ideal for use in applications where flexibility is a concern, such as in telecommunications and electrical conduits.

- Easy Installation: HDPE duct couplers are easy to install and require no special tools or equipment. They can be installed quickly and easily by one person, which can save time and money on installation costs.

- Leak-Free: HDPE duct couplers are designed to create a tight, leak-free seal between two or more sections of ductwork. This helps to prevent leaks and other issues that can cause damage to underground utilities and infrastructure.

- Wide Range of Sizes: HDPE duct couplers are available in a wide range of sizes, from small diameters of 20mm up to large diameters of 630mm or more. This makes them suitable for use in a variety of applications, from residential and commercial plumbing to large-scale industrial piping systems.

- Durability: HDPE duct couplers are made from high-density polyethylene, which is a durable and long-lasting material. This means that they are able to withstand heavy loads and pressures, making them ideal for use in underground applications.

- High Strength: HDPE duct couplers are made from high-density polyethylene, which is a strong and durable material. This means that they are able to withstand heavy loads and pressures, making them ideal for use in underground applications.

- Easy Installation: HDPE duct couplers are easy to install and require no special tools or equipment. They can be installed quickly and easily by one person, which can save time and money on installation costs.

- Low Maintenance: HDPE duct couplers require very little maintenance and are designed to last for many years without the need for replacement or repairs. This can help to reduce maintenance costs and downtime for businesses and organizations.